Printing Fume Control

The move from solvent to aqueous inks has reduced some hazardous emissions, but air quality issues can remain for commercial and office printing, which might require printing fume control.

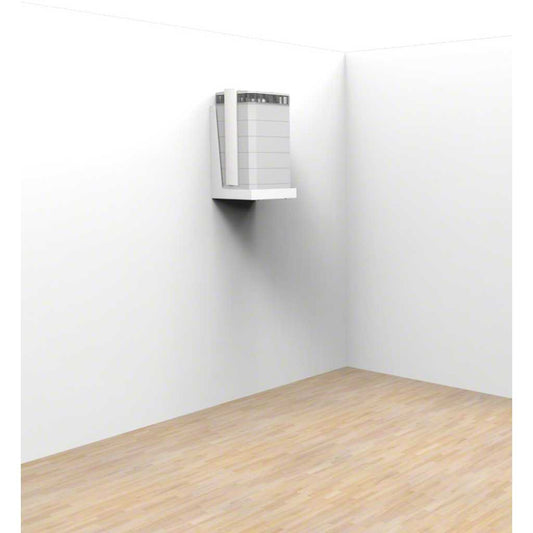

Controlling the air quality in a printing environment can be challenging, especially when temperature and humidity levels have to be controlled at the same time. Professional air purifiers offer, however, offer an effective and cost efficient solution.